Specialists in on-line measurement of cyanide, WAD cyanide, acid, lime and other reagents in mining solutions.

Process Analytical Systems analyzers are purpose designed for the application at hand. This simplifies the equipment, offering the user a package that is easy to understand and maintain. The analyzer HMI (Human Machine Interface) uses recognisable Engineering Units. Personnel adapt to use our equipment with ease. PAS analyzers are installed in over 30 countries around the world. Units are mainly deployed on mining sites, where our ability to sample mining slurries and present clear process solutions for analysis is one of the key factors for success. Analyzers are designed to cope with real-world harsh plant environments and are built to handle dirty power, dust and vibration. Typical enclosures are IP65 GRP (Glass Reinforced Plastic). All exposed metal parts are Stainless Steel. When required the equipment is supplied pre-installed in a small insulated cabin. The cabin can be fitted with an optional air-conditioner for hot climates, or heater for cold climates. We have experience in coping with all temperature extremes. All our analyzers offer industry standard signal interfaces to the plant process computers. Various PLC/DCS bus interfaces are available, as are OPC drivers. Our analyzers have proven track records. We only use analytical methods that are proven, reliable and drift free in plant environments. Our units are designed to need minimal routine maintenance. They run automatic self-cleaning cycles that further reduce the maintenance effort. The units have low reagent usage.

- TAC 1000 Cyanide and pH Analyser and Controller

- WAD 1000-S Cyanide Analyser

- pH 1000 Controller

- ACID 1000 Acid Analyser and Controller

- Support and Spares

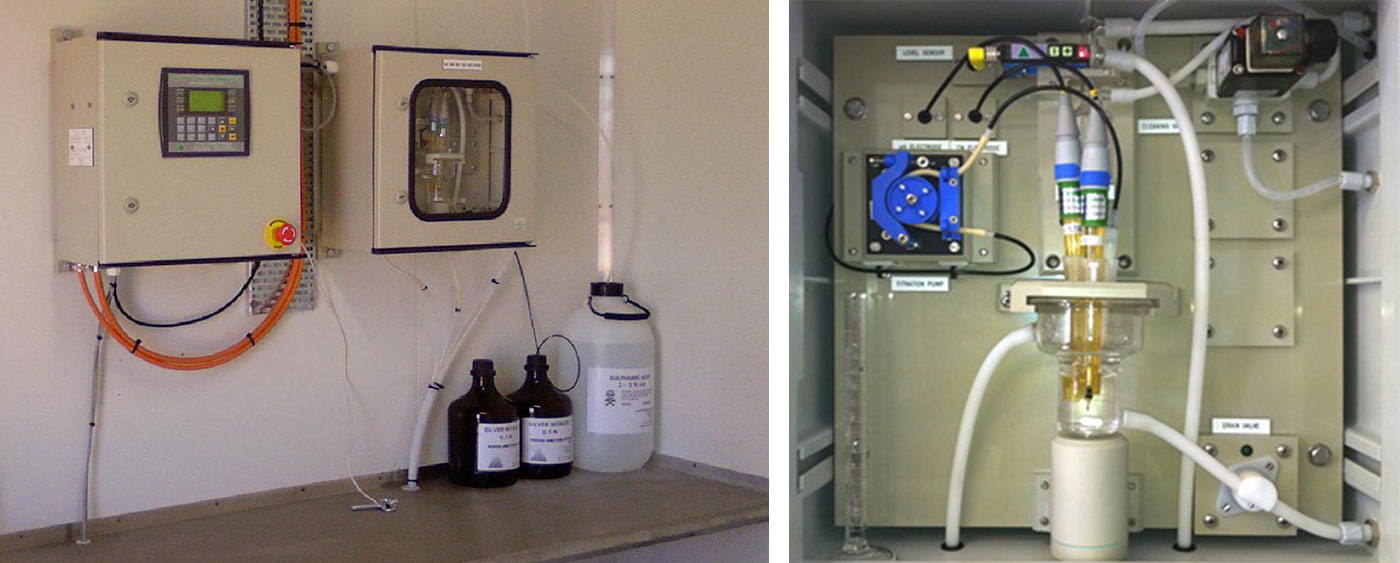

TAC 1000 – Cyanide and pH Analyser and Controller

The TAC 1000 is a cost effective Cyanide analyzer with integrated sampling system. It monitors cyanide level on one, two or three process stream, and boosts your profits.

In the Basic configuration the unit monitors the free cyanide concentration in a Gold plant. It has a simple user interface with a keypad for date entry and a LCD screen for displaying information.

The Control option connects the TAC 1000 to a cyanide dosing system. It achieves good control using a sophisticated cyanide addition algorithm.

TAC 1000 CYANIDE ANALYSER

The TAC 1000 is a titration based Cyanide and pH Analyser with integrated sampling system. PAS has over 20 years of cyanide measurement experience. Our TAC 1000 offers the most advanced sampling system and cyanide detection methodology.

The TAC 1000 is a cost effective solution to measure cyanide on-line. Real-time measurement allows for automatic cyanide control. Running closer to set-point optimises and reduces cyanide consumption while ensuring best product recovery. There is less cyanide (Free and WAD) reporting to tailings. Some plants are able to avoid having to do cyanide destruction by optimising cyanide dosing in the leach.

All equipment is housed in a corrosion free enclosures designed for use within harsh plant environments.

THE SAMPLING SYSTEM

A well proven, patented, self cleaning sampling system guarantees a supply of fresh sample.

INSTALLATIONS

The TAC system is well proven and units are installed in many countries around the world.

CYANIDE CONTROL

The optional control algorithm built into TAC 1000 is the culmination of over 30 man years of experience by our team in handling and implementing cyanide control on Gold/Silver plants. Due to the nature of the application, cyanide control is a complex problem where off the shelf PID control solutions offer less than optimal results. The natural complexity presents challenges. The PAS predictive control algorithm can be configured to give good control response under trying circumstance. It is robust enough to withstand reasonable plant changes without requiring re-tuning. Our cyanide control algorithm has a proven track record in reagent savings. The payback period of our systems is often “startlingly short”. An added economic benefit of tighter cyanide control is higher product yield.

KEY BENEFITS

- Rugged, low maintenance, low cost system.

- Simple to install by end user.

- Self cleaning sampling system.

- Process visibility through automated determination and reporting of cyanide levels.

- Reduction of cyanide consumption.

- Accurate control of cyanide levels allows for process optimization.

- Accurate data logging and reporting.

- Reduces manual procedures.

OPTION

- Second and third stream capability.

- pH measurement and pH control.

- Cyanide control options.

- Optional printer for hard copy of results and plant status providing supervisors with a history of plant performance.

- Signal interface via Modbus.

- Cellular phone modem for remote configuration and result sending via text message.

- Packaged for outside operation.

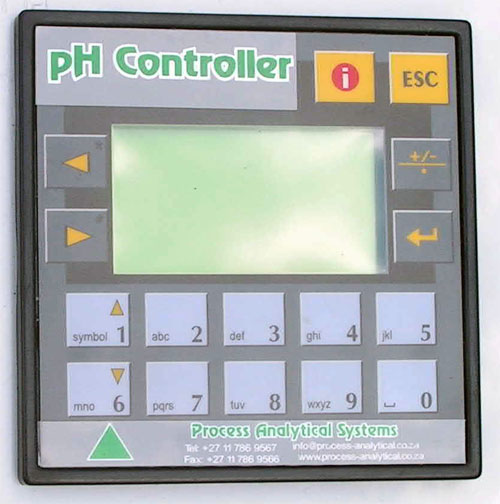

pH 1000 Controller

pH 1000 Controller

WHAT IS THE pH1000 CONTROLLER?

The pH controller is used in conjunction with a TAC 1000, WAD 1000-S or other pH measuring equipment. It interfaces with Lime dosing equipment to achieve pH control.

ACID 1000 – Acid Analyser and Controller

The ACID/LIME 1000 is a titration based Acid, Lime and pH analyser with integrated sampling system. Similar to the TAC 1000 technology, it determines Acid or Lime levels on-line.

The Acid 1000 monitors the acid concentration in a hydrometallurgical process plant. It has a simple user interface with a keypad for data entry and an LCD screen for displaying information.

THE ANALYSER

All equipment is housed in a rust free enclosures designed for use within harsh plant environments.

THE SAMPLING SYSTEM

A well proven, patented, self cleaning sampling system guarantees a supply of fresh sample.

INSTALLATIONS

The system is well proven and units are installed in 20 countries on five continents.

KEY BENEFITS

- Rugged, low maintenance, low cost system.

- Simple to install by end user.

- Self cleaning sampling system.

- Process visibility through automated determination and reporting of cyanide levels.

- Frequent accurate data allows for application of closed loop control.

- Accurate control of cyanide levels allows for process optimization.

- Accurate data logging and reporting.

- Reduces manual procedures.

OPTION

- Printer for hard copy of results and plant status providing supervisors with a history of plant performance.

- Signal interface via Modbus.

- Cellular phone modem for remote configuration and result sending via text message.

- Printer for hard copy of results and plant status providing supervisors with a history of plant performance.

- Control options.

- Packaged for outside operation.

- Installation in custom cabin.

Support and Spares

Most of our analyzers are installed in very remote parts of the world; that is the nature of the mining industry. Our equipment is designed to be reliable and easy to maintain. If something does go faulty, all items such as valves, pumps etc. are designed to be “End user” replaceable. Most items are swopped out by undoing 4 screws. The electrical connection is made with a keyed plug that can only be connected one way.

Process Analytical Systems keeps a vast range of spares in stock to offer outstanding support for our units. We keep all spares of current analyzers in stock and can usually dispatch next day by courier to site.

GSM interface

Our current analyzers interface to the GSM cellular phone networks. This allows for remote support of the analyzers. We can diagnose faults and even repair them remotely.

The analyzers can send Alarms or results as SMS to ant cell phone. The unit can be configured to give a daily report on how the plant performed over the last 24 hrs. All this is done at a remarkable low monthly cost.